The Australian Human Microbiome Biobank (AHMB) is a custom-built, state-of-the-art facility supported by grant funding from the Medical Research Foundation Fund. Securing funding validated the importance and potential impact of our research endeavours. It was a moment of celebration and gratitude, knowing that we had the support and resources necessary to bring our vision to life. We remain committed to stewarding these funds responsibly and making the most of every opportunity they afford us.

As we look back on the journey of building the ideal lab, we’re filled with a sense of pride and accomplishment. From the initial spark of inspiration to the final installation of equipment, every step along the way has been a learning experience – testing our dedication, perseverance, and teamwork. Join us as we take you through the retrospective of our lab-building process, sharing insights, challenges, and triumphs along the way.

June 2023

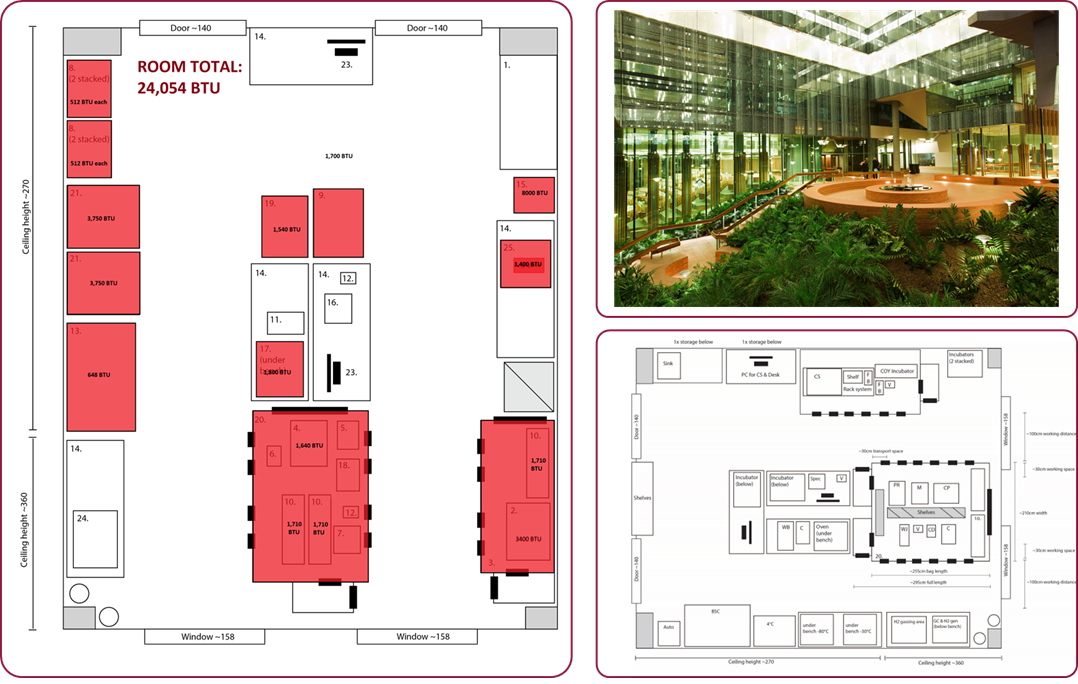

Room Layout Proposal:

Crafting the layout of our lab was a collaborative effort that involved engineers, designers, and members of our research team. We wanted to create a space that was not only functional and efficient but also conducive to collaboration and creativity. Through countless iterations and revisions, we arrived at a layout that maximised space utilisation, optimised workflow, and fostered a sense of community among our researchers. Implementing robust biosafety measures also gave us peace of mind knowing that our lab was a safe and secure environment for everyone. Even the seemingly small details, like door design, were carefully considered to enhance the functionality and safety of our lab. We consulted with door manufacturers to select options that met fire safety standards, minimised contamination risks, and facilitated smooth traffic flow.

July 2023

Consultation and purchasing:

With a vision of how to create a state-of-the-art laboratory that would push the boundaries of scientific research and innovation, we continued by consulting with experts in lab design and equipment suppliers, gathering quotes, and determining what the lab could be. Each conversation helped shape our understanding of what was possible within our budget and set the stage for the rest of the journey. In particular, the consultation experience was critical in the development of our custom-built anaerobic chambers. Months of discussions and development drawings went into their creation, and as the cornerstone of the lab it was critical we got them right.

With the quotes in hand and funding secured, we wasted no time in acquiring the large-scale equipment that would form the backbone of our lab. From cutting-edge flow cytometers to specialised storage solutions, each piece of equipment was carefully selected to meet our research needs and propel us towards our goals. In addition to the big-ticket items, we also focused on acquiring the smaller equipment and consumables that are essential for day-to-day lab operations. Pipettes and petri dishes, lab coats and safety goggles; every item plays a crucial role in the functioning of our lab. Building a well-stocked inventory ensured that our researchers had everything they needed to hit the ground running from day one.

December 2023

Equipment/Consumables Delivery and Installation:

The most exhilarating phase of our lab-building journey was undoubtedly the delivery and installation of the equipment that would bring our research aspirations to life. It was a culmination of months of planning, coordination, and anticipation, as each piece of equipment represented a new tool for discovery and innovation.

Cytek Aurora FACS Cell Sorter

An early highlight of our equipment acquisitions was the Cytek Aurora Flow Cytometer. Its advanced spectral technology and high-resolution capabilities opens up a world of possibilities for our researchers, allowing them to analyse and sort cells with unparalleled precision and efficiency. Our flow expert, Allison, was so excited to see it arrive and get to work on it!

Plate Reader and Spectrophotometer

For quantitative analysis of biological samples, we purchased a VarioSkan LUX Plate Reader and GeneSys Spectrophotometer. These instruments enable precise measurement of absorbance, fluorescence, and luminescence, facilitating a wide range of biochemical assays and experiments.

Underbench Fridge and Freezer

To store reagents, samples, and other perishable materials, we installed Pinnacle Underbench Fridge and Freezer units. These high-performance appliances provide the facility with ample storage capacity and reliable temperature control, safeguarding valuable research assets.

January 2024

Ultra-low temperature Freezers

Biobanks need a lot of storage. We are, after all, a storage facility! In January, we received delivery of five ULT Freezers which allow us to store our isolates at -80°C. This provides us with secure long-term storage for valuable biological samples.

PIXL Colony Picker

With so many samples, and so many isolates from those samples, we needed a high-throughput way to pick and choose the isolates. An automated colony picker, the PIXL, was essential for our microbiology research endeavours. The colony picker recognises and selects the isolates from a plate, so we can move them into conditions that they will grow in. This allows us to transfer each microbial isolate into a unique storage location, so we can characterise and store it as needed. Matthew came in to be our expert trainer, and got the team up to speed with using this state-of-the-art equipment.

February 2024

Lab Coats and Safety Equipment

Ensuring the safety of our researchers is paramount, which is why we provide lab coats, safety goggles, gloves, and other personal protective equipment. These essential items protect our team members from chemical spills, biological hazards, and other occupational risks, allowing them to work confidently and securely in our lab. Usually, lab coats are not a cause for celebration in a lab. However, for us, the day they arrived was one of great excitement as these were the first items we received with AHMB branding! It all began to feel a bit more “real”.

LVL Barcode Reader, Capper Decapper and Tubes

Critical to a biobank, sample tracking and management was so important to the build out of AHMB. We integrated LVL Barcode Readers, Capper Decappers, and a wide range of specialised tubes to streamline sample handling processes, minimise error, and enhance data traceability throughout our work. Look at the cool barcoding we have for each and every tube we create in the lab – such an easy way to track everything!

March 2024

Metal FACS Base and Reinforced Tables

Our lab is centred around two large, custom-built, state-of-the-art anaerobic chambers – both filled with all the equipment needed to support our biobanking setup. That is a lot of equipment! To support this equipment and keep everyone safe, we opted for sturdy and customised reinforced tables from a local supplier – Everything Metal, Brisbane. These robust workstations provide a stable platform for instrument installation and operation, with ample space for additional accessories. And they are in AHMB red!

April 2024

Anaerobic Chamber Delivery

The day finally arrived! Our custom anaerobic chambers had been on a journey, to say the least! Having been built in the USA, air-freighted to Melbourne and shipped up to Brisbane, we were glad to finally see the chamber crates arrive at TRI. Now, just need to get them up to our lab…

May 2024

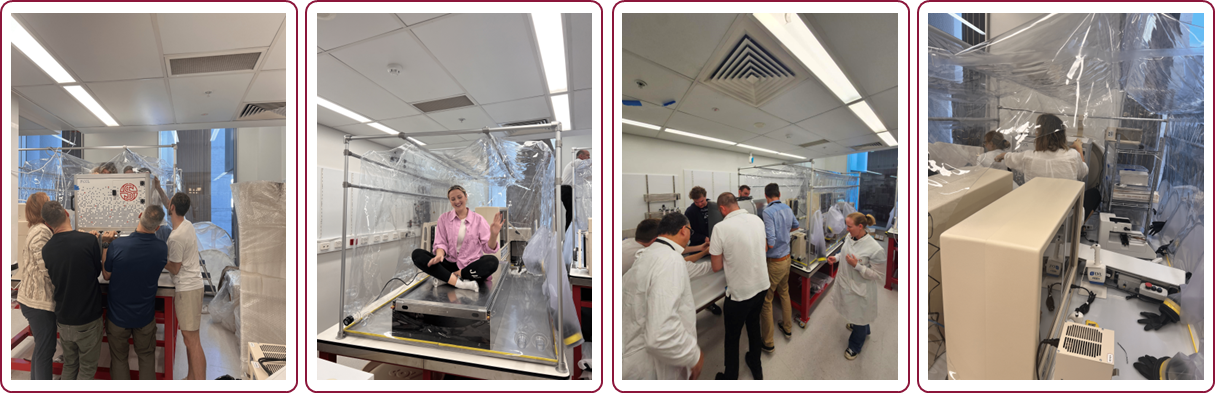

COY Anaerobic Chamber Build

For studies requiring anaerobic conditions, we required chambers that could maintain these conditions for us to ensure the viability and success of our isolates. These chambers provide a controlled environment free of oxygen, enabling researchers to culture and manipulate anaerobic microorganisms with precision and accuracy.

We have two chambers – one houses our Flow Cytometer, allowing precise identification and sorting of individual microbes, while the other houses all our banking equipment from the plate reader to the colony picker. This build-out took two weeks, and the gas exchange to get the chambers to anaerobic conditions took another two weeks! But it was all worth it.

Equipment Move

Now for the fun part – to fill the chambers with the required equipment and get our lab in working order. We started by moving the Cytek Aurora into its dedicated chamber (a feat in itself). Next, we moved onto getting our PIXL colony picker, plate reader, and all our other equipment into our 2m x 3m central chamber.

Lab Kit Out

All that was left was to get our lab in working order. With the dedicated work of our AHMB team, we managed to set up the lab and move every piece of consumables and reagents in, so we were ready to start working! What an amazing achievement from the team.

June 2024

As we reflect on the journey of building our ideal lab, we’re grateful for the support and collaboration of everyone involved. From the initial consultation to the final installation of equipment, each stage of the process was a testament to our shared vision, dedication, and perseverance. Our lab stands as a testament to what can be achieved when passion, expertise, and teamwork come together in pursuit of a common goal. We look forward to the discoveries and innovations that lie ahead as we continue to push the boundaries of scientific research and exploration!